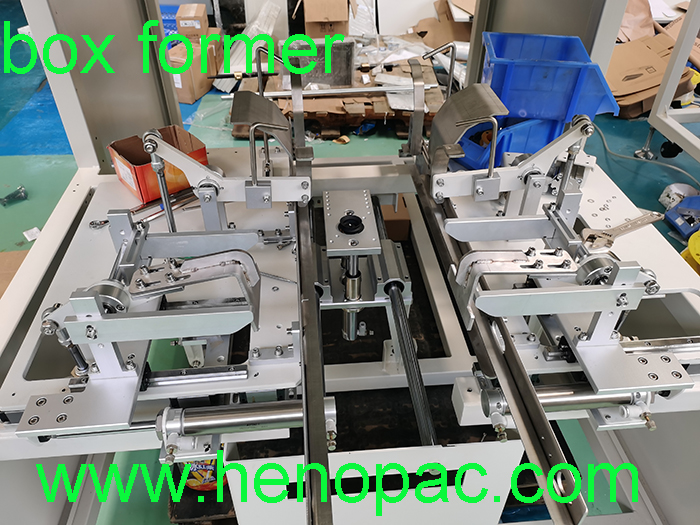

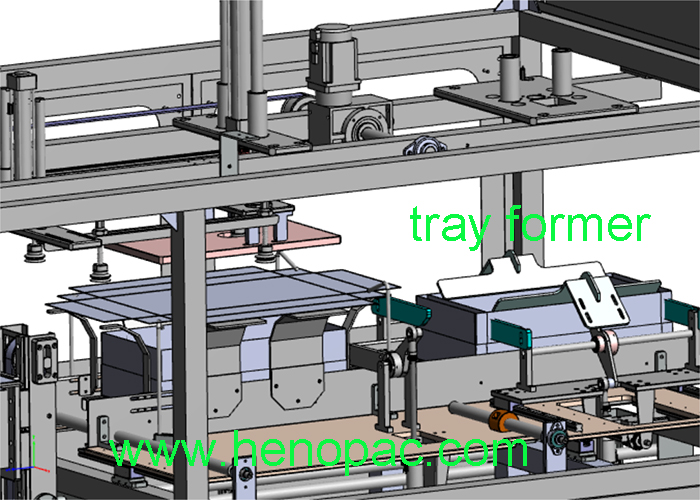

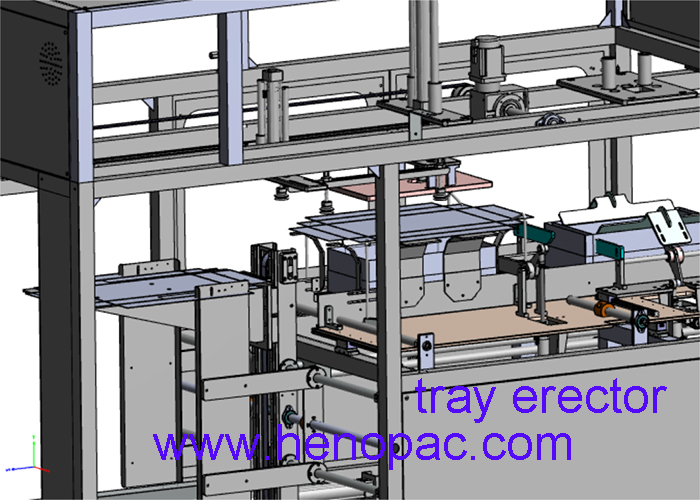

High speed tray former

lid and tray former automatic forming machine

- automatic lid former

- self-lock tray former

- automatic lid tray erector

- high speed tray erector

- Product description: lid and tray former automatic forming machine automatic tray former automatic tray erector automatic box erector automatic box former

lid and tray folding and forming machine automatic tray former automatic tray erector automatic box erector automatic box former

HENOPAC’s tray forming and self-locking packing machine which controlled by PLC and operated by HIMI system. It is the tray former without glue nor adhesive taper sealing. It is widely applied on the electronics industry, toys, food fashion design, car industry and so on.

Nowadays, it is more popular applied in E-commerce warehouse industry.

lid and tray folding and forming machine No need to stop the machine when adding the tray cardboard on the magazine.It is the tray former that pulling from the top and forming from the bottom stamping molding system.With its small footprint design, it can widely applied for the E-commerce packaging warehouse system.Automatic tray erecting machine can highly improve the packing speed ,what’s more, it can also save labor ,save money for the enterprises.

With the intelligent HMI control system, let the users operate the machine easier and faster.

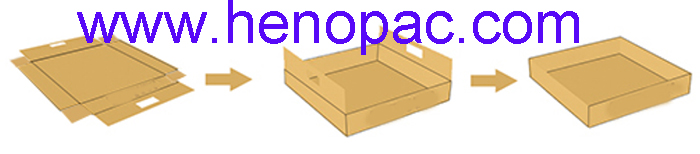

lid and tray folding and forming machine working process:

Ø Remagenesis and feeding mechanism : pick up the tray cardboard by sucker ,then Remagenesis and feeds it to the forming workstaion . pressing forming by the alumimum mould.

Ø The tray cardboard rack ,it can stack 200-300pcs tray cardoard. It can automatic up and down according to the number of the tray cardboard.

Ø Pressing fomring mechanism: it press the tray cardboard froming the tray .it keep four side flaps of tray keep stand.

Ø Folding and buckle flaps mechanism: it automatic fold two sides flaps and buckle them well . the tray cardboard will finished forming the tray .

blank feeder Pressing forming Folding and buckle flaps finished

lid and tray folding and forming machine technical and parameter:

|

Power supply |

220V 50/60HZ |

|

Packing speed |

10~15 TRAY/MIN |

|

Packing material |

Corrugated case blanks |

|

Packing size |

Diameter:L90~140*W70~120*H45~60mm(Customized build) |

|

Table height |

650mm |

|

Air sauce |

0.4~0.6Mpa |

|

Air consumption |

0.2nm³/min |

|

Machine weight |

500~800KG |

|

Machine dimension |

L1900×W1600×H1900mm |

lid and tray folding and forming machine automatic tray former core component :

|

No. |

Item |

Brand |

function |

|

1 |

HMI touch screen |

MCGS/China |

Control panel |

|

2 |

PLC |

Delta/Taiwan |

Control system |

|

3 |

Inverter |

Delta/Taiwan |

drive |

|

4 |

Senview/China |

||

|

5 |

Fibre Optical Sensors |

Senview/China |

|

|

6 |

Cylinder |

Airtac/Taiwan |

|

|

7 |

solenoid valve |

Airtac/Taiwan |

|

|

8 |

vacuum cup |

Airbest/China |

|

|

9 |

vacuum generator |

Airbest/China |

|

|

10 |

Lower voltage electrical parts |

Schneider/France |

Protect |

|

11 |

buttom switch |

Schneider/France |

Operate |

|

12 |

sychronous belt and wheel |

Yiheda/China |

Transmission |

|

13 |

Gasholder |

China |

Stable air soruce |

|

14 |

Acrylic plate |

tawny |

visible window |

Ø Sheet metal material:304 stainless , cold-rolled sheet 45# steeI ron box

Ø Component material: 304 stainless , 45# steeI ron box,aluminum

Surface treatment of machined parts: galvanize or chromeplate extra stainless ste

Automatic tray erector options:

PLC and HMI brand

Martail : can adopt the stainless steel

l

Categories

- semi-auto stretch wrapper

- fully auto stretch wrapper

- pallet strapping machine

- automatic edgeboard applicator

- High speed tray former

- case erector

- Bag-in-box maker & inserter

- case packer

- Bag sealing and fold machine

- case sealer

- pallet dispenser/pallet magazine

- palletizer robot system

- pallet handing solutions

- palletizer robot relate

- mask machine

- mask packing machine

Latest News

Contact Us

Contact: David lee

Phone: +86 18680322634

Tel: 86-755-21508489

Add: Junyi Industries area, Lixin South Road, Foyong,Bao an District, Shenzhen, China

henopac

henopac henopac

henopac