High speed tray former

high speed Hot melt gluing tray former

- Product description: high speed Hot melt gluing tray former box former tray erector

High speed hot melt gluing tray former

automatic hot melt gluingTray former hot melt gluing tray erector hot melt gluing box former manufacturer formadora de bandeja de colagem a quente de alta velocidade cola de fusão a quente automática Formador de bandejas eretor de bandeja de cola de derretimento a quente ex-fabricante de caixa de colagem a quente ถาดกาวร้อนละลายความเร็วสูงในอดีต กาวร้อนละลายอัตโนมัติ ตัวสร้างถาดกาวร้อนละลาย อดีตผู้ผลิตกล่องกาวร้อนละลาย khay dán nóng chảy tốc độ cao trước đây keo nóng chảy tự động thợ lắp khay dán nóng chảy nhà sản xuất cũ hộp dán nóng chảy formadora de bandejas de encolado en caliente de alta velocidad encolado automático en caliente erector de bandeja de encolado termofusible fabricante de cajas de encolado termofusible

Technical parameter:

|

Item |

|

Note |

|

Forming speed: |

20-30pcs/min |

|

|

Pakcing size: |

According to customer tray size |

|

|

Packaging materail |

Corrugated case blanks/ hotmelt glue |

|

|

Conveyor line heihgt : |

600mm |

Can customized |

|

Airpressure : |

0.6-0.8Mpa |

|

|

voltage: |

3KW;380V 60Hz |

|

|

Machine size: |

L1800*W1400*H1780mm |

|

|

Machine weight: |

580kg |

|

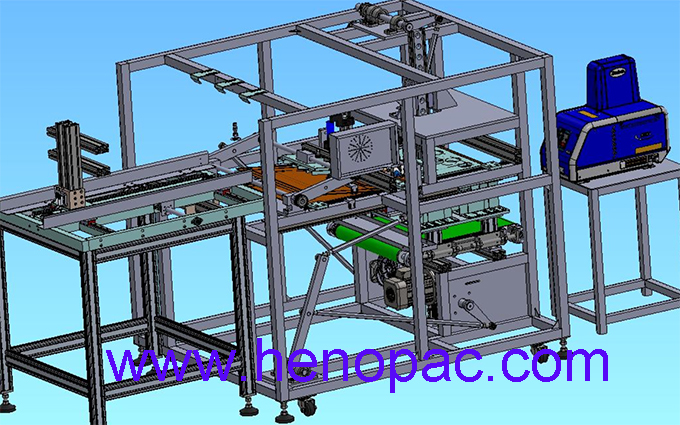

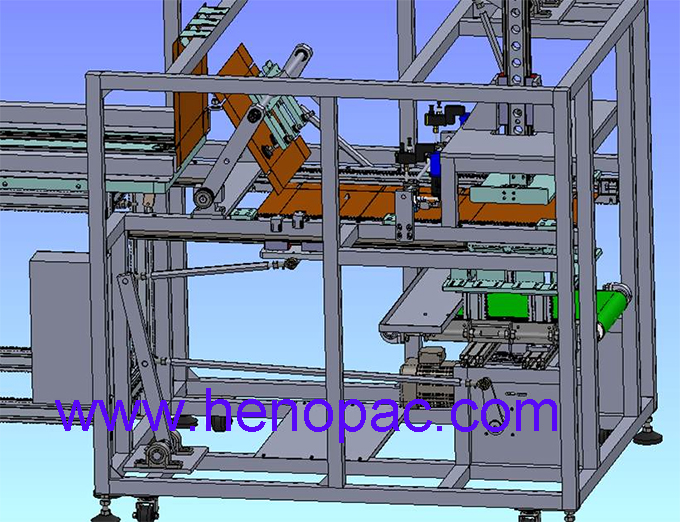

machine pictue and function:

●adopt the international advance technolody to made the machine ,adopt high quality component,electrical parts and pneumatic parts

● Fit for the one section time one kind size tray ,if you need change the size of the tray , it need manual adjustable, the adjustable time is about 10-15mins

● Lightweight, stable machine performance, no vibration during operation, stable operation, long life and high efficiency;

● It can single use or connect and work with the automatic packing line

2,the working process :

blank feeder Gluing and press forming Finished forming

3,the detail inner structure working process :

|

vertical tray stack sturcture it can automatic moving accoring to the quantity of the blanks,it can stack about 200-300 pcs flat cardboard blanks |

|

The Nordson gluing machine

|

|

press forming sturcture adopt the linkage to press the blank in the mould to forming become the tray |

|

Tray exit postion |

|

the tray forming structure : it press forming and hot melt gluing to bond

|

4,core component:

|

No. |

Item |

brand |

Function |

|

1 |

HMI touch screen |

MCGS/China |

Control panel |

|

2 |

PLC |

Delta/Taiwan |

Control system |

|

3 |

Servo motor and drive |

Delta/Taiwan |

Pick up drive |

|

4 |

Inverter |

Delta/Taiwan |

drive |

|

5 |

Hot melt gluer |

Nordson/USA |

· Spray adhesive box |

|

6 |

motor with brake |

CMG/China |

|

|

7 |

Gear box |

CMG/China |

|

|

8 |

Senview/China |

||

|

9 |

Fibre Optical Sensors |

Senview/China |

|

|

10 |

Cylinder |

Airtac/Taiwan |

|

|

11 |

solenoid valve |

Airtac/Taiwan |

|

|

12 |

vacuum cup |

Airbest/China |

|

|

13 |

vacuum generator |

Airbest/China |

|

|

14 |

Lower voltage electrical parts |

Schneider/France |

Protect |

|

15 |

buttom switch |

Schneider/France |

Operate |

|

16 |

sychronous belt and wheel |

Yiheda/China |

Transmission |

|

17 |

Gasholder |

China |

Stable air soruce |

|

18 |

Acrylic plate |

tawny |

visible window |

Sheet metal material:304 stainless , cold-rolled sheet 45# steeI ron box

Component material: 304 stainless , 45# steeI ron box,aluminum

Surface treatment of machined parts: galvanize or chromeplate extra stainless steel

Categories

- semi-auto stretch wrapper

- fully auto stretch wrapper

- pallet strapping machine

- automatic edgeboard applicator

- High speed tray former

- case erector

- Bag-in-box maker & inserter

- case packer

- Bag sealing and fold machine

- case sealer

- pallet dispenser/pallet magazine

- palletizer robot system

- pallet handing solutions

- palletizer robot relate

- mask machine

- mask packing machine

Latest News

Contact Us

Contact: David lee

Phone: +86 18680322634

Tel: 86-755-21508489

Add: Junyi Industries area, Lixin South Road, Foyong,Bao an District, Shenzhen, China

henopac

henopac henopac

henopac