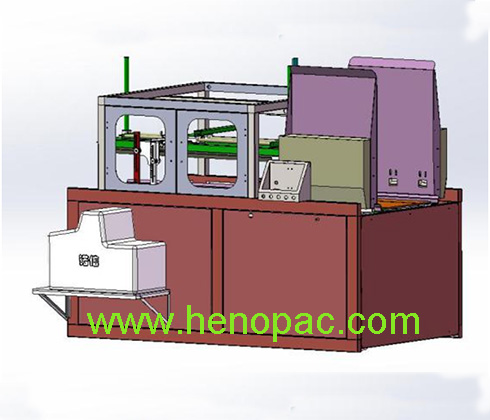

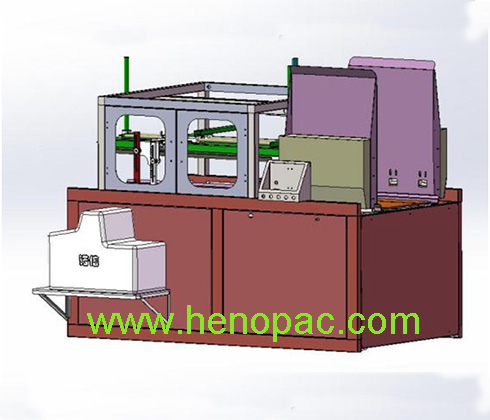

case erector

hot melt glue case erectors

- USA Nordson gluing machine

- Automatic hot Melt Glue Case Erectors

- Hot Melt Glue high speed Case Erectors

- High Speed case erector /bottom sealer with hot melt sealing

- Product description: hot melt glue case erectors Carton Erector Machine With Hot Melt Glue Systems Hot Melt Glue Case Erectors Hot-melt glue case erector High Speed case erector /bottom sealer with hot melt sealing

High speed hot melt case erector

(The picture just for reference)

Technical and parameter:

|

Machine model |

K30T |

|

Production speed |

22-25 case/min max (Stepless) |

|

Forming type |

Horizontal case erector |

|

Carton box size |

L240-510*W170-400*H120-400mm But the max size and min size can’t concurrence For example: Max length+width≤900,width+height≤800. minimum height+width/2≥215. if have other special carton box size ,please supply detail Length*width*height |

|

Voltage and power |

Single phase 220V 50Hz or 3 phase 380V 50Hz 0.75Kw |

|

Necessary air pressure |

6kg/cm3 |

|

air consumption |

450NL/min |

|

Fit for the adhesive tape width |

48,60mm (alternative use) |

|

The side stick length |

45-60mm |

|

Carton storage |

About 80 pcs (according to the thickness of the carton box ,it can feeder carton box any time when the machine is running) |

|

Machine dimension |

L2300xW1210xH1750mm |

|

Machine weight

|

650KG

|

|

Table height |

950mm |

machine feature:

Henopac high speed hot melt gluing case erector transmission adopt the mechanical type. It consist of the cam’s rotational motion, the reciprocating motion push follower make the reciprocating motion or the pendular device (such as ,pick up carton box,carton box forming,bottom flaps fold), Nordson hot melt gluing machine. the cam device structure is very compact that it fit for require follower does intermittent movement,the cam device and linkage control the machine running smooth .

The advantages:

It is more accuracy,faster and more stable , little space location ,simple operate,easy to adjustable compare with the tradition pneumatic type high speed case erector.

not need stop the machine runing when feeder the carton boxes ,It just modify the model in the touch screen ,case forming not need stop the machine.

is better to solve the vertical case erector fold the wrong position of the square carton problem.

It not need the conveyor line belt to clamp conveyor ,it can better to solve the carton box malposition problem when the belt conveyor is not in the synchronous.

Safety and alarm:

u It can automatic remind labor to feeder the carton

u it has the pick up carton fault alarm function

u it has the carton box fault forming alarm function

u Safety matters: has the safety door, when the door open that the machine stop running

The machine will stop running when any fault happen , total fault be showed in the touch screen ,it can easy to know about it and fast to solve it.

Core component:

u Motor:TECO/Taiwan

u PLC:Siemens/Germany

u Touch screen(HMI):MCGS/China

u Inverter: Schneider/France

u Photocell:Sick/Germany

u Cylinder:SMC/Japan top flaps fold use,Airtac/Taiwan for the stack use

u Valve:SMC/Japan ,Airtac/Taiwan

u Sucker cup:CONVUM/Japan

u Lower voltage electrical parts: Schneider/France

u Bearing :C&U/China

u Sliding Rail guide:Hiwin/Taiwan

Categories

- semi-auto stretch wrapper

- fully auto stretch wrapper

- pallet strapping machine

- automatic edgeboard applicator

- High speed tray former

- case erector

- Bag-in-box maker & inserter

- case packer

- Bag sealing and fold machine

- case sealer

- pallet dispenser/pallet magazine

- palletizer robot system

- pallet handing solutions

- palletizer robot relate

- mask machine

- mask packing machine

Latest News

Contact Us

Contact: David lee

Phone: +86 18680322634

Tel: 86-755-21508489

Add: Junyi Industries area, Lixin South Road, Foyong,Bao an District, Shenzhen, China

henopac

henopac henopac

henopac