palletizer robot relate

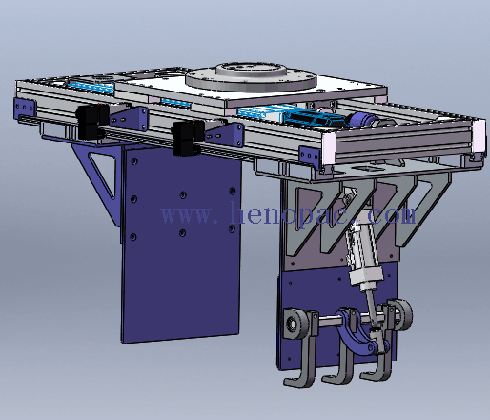

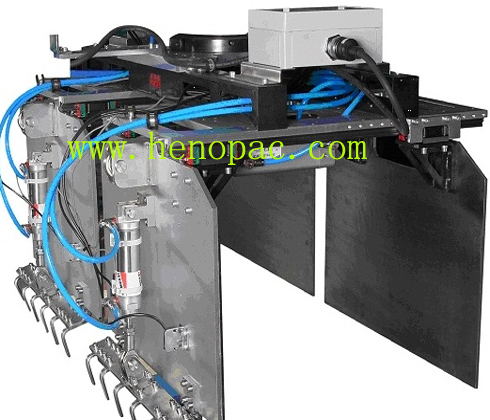

carton box palletizer robot gripper

- Product description: Bag Gripper end effectors offer end-of-line, pick-and-place palletizing solutions.carton box palletizer robot gripper case robot gripper

carton box palletizer robot gripper palleting robot system case robot gripper

Do you have a detailed inquiry regarding our palletising solutions?

Simply use our inquiry form. We will contact you as soon as possible.

To the inquiry form

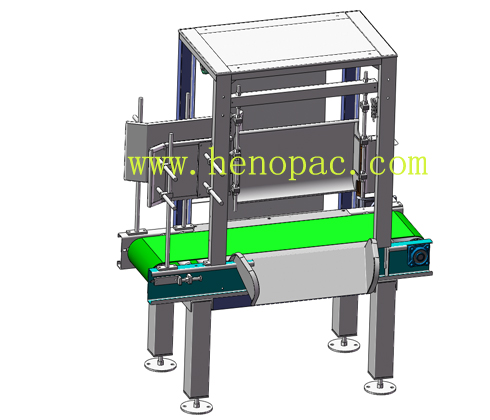

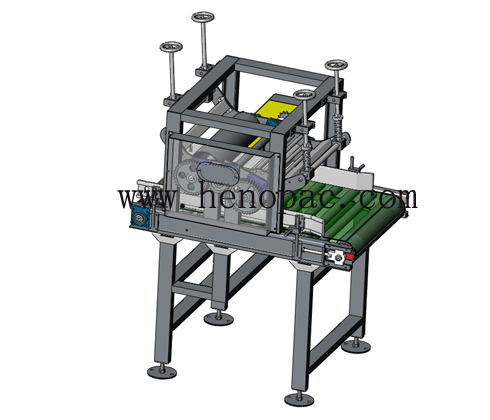

Innovative palletising technology with state-of-the-art technology

The HENOPAC palletizer robot sytem palletises and depalletises various types of packages using specifically developed gripper elements. The HENOPAC interface control ensures a user-friendly handling, as well as a flexible adjustment to changing conditions of use. Even complex processes with varying basic parameters can be solved in a reliable and efficient way.

HENOPAC paleltizer robot systems feature energy efficiency and maximum accuracy when the layers are formed on pallets. They are also suitable for bagged products and can be reconfigured very easily for frequent product changes.

• High flexibility for various tasks

• Little floor space required due to compact design

• Exchangeable grippers for picking up various packaged goods

• Simple change of the packing pattern – at the touch of a button or fully automatic through barcode recognition

• Up to 1,900 units per hour, depending on the model

• Reliable, even under extreme conditions

HENOPAC paleltizer robot systems can be equipped with different grippers. This ensures high flexibility. You can palletise different sized load units on the same pallet using gripping systems that can stack packages from above into available gaps.

Fork gripper

Whether handling bagged goods or cardboard boxes: the fork gripper ensures reliable, gentle and precise stacking of both product types. It can handle up to 600 units per hour.

Double fork gripper

The powerful double fork gripper stacks bagged goods and cardboard boxes with a capacity of up to 900 units per hour; this is also possible by moving two units per travel path.

Finger gripper

The finger gripper is a high capacity tool for stable bags. It can palletise up to 1,200 bags per hour.

Double finger gripper

The double finger gripper is used if large quantities of stable bags need to be palletised. It can position up to 1,900 bags per hour for the palletising process.

Pallet gripping device

The installation of a pallet gripping device allows for feeding the empty pallets without an additional empty pallet conveyor.

Suction gripper

The suction gripper is recommended for bundles with suctionable surfaces: it can stack up to 400 bundles per hour while gently handling the product. Even unstable packaged goods can be palletised reliably.

Parallel gripper

The parallel gripper performs especially well when palletising stable bundles with parallel side walls, i.e. cardboard boxes: it can stack up to 600 cardboard boxes per hour.

Special gripper

For individual requirements, special gripping systems are developed and dimensioned for the specific products and performance characteristics.

The HENOPAC carton box Gripper end effectors offer end-of-line, pick-and-place palletizing solutions. The henopac case Gripper utilizes a simplified, field adjustable, lightweight design to provide our customers with the fastest, most reliable case Gripper available today.

Used for Brown corrugated box Palletizing

Bag size range 10-50kg Corrugated box

Packing speed 12-15 Cartons/min

Carton size range L200-480xW250-350xH200-400mm

Machine Dimension L450xW500x450mm

Fit for robot type palletizer robot

ABB IRB460 ABB IRB660

KUKA KR 700 PA

Yasakawa motorman-MH110 MH180 MH180-120

Fanuc M-410iB/M-410iC

Kawasaki CP180L CP300L

Nachi LP130/180/210-01

Weight of gripper 40kg

Pneumatic components SMC/Japan

Material Aluminum alloy

Option High speed exchange gripper

Categories

- semi-auto stretch wrapper

- fully auto stretch wrapper

- pallet strapping machine

- automatic edgeboard applicator

- High speed tray former

- case erector

- Bag-in-box maker & inserter

- case packer

- Bag sealing and fold machine

- case sealer

- pallet dispenser/pallet magazine

- palletizer robot system

- pallet handing solutions

- palletizer robot relate

- mask machine

- mask packing machine

Latest News

Contact Us

Contact: David lee

Phone: +86 18680322634

Tel: 86-755-21508489

Add: Junyi Industries area, Lixin South Road, Foyong,Bao an District, Shenzhen, China

henopac

henopac henopac

henopac