fully auto stretch wrapper

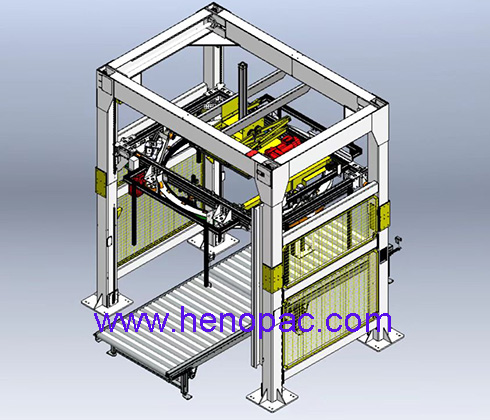

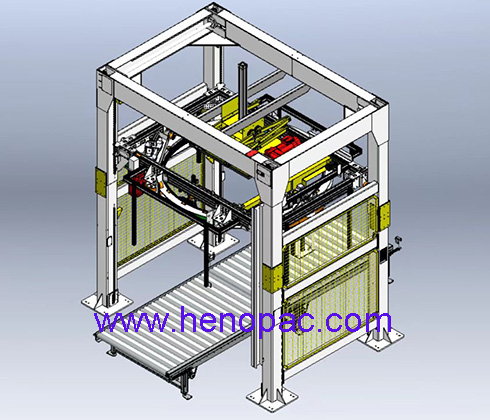

Rotary Ring type Pallet Wrapper

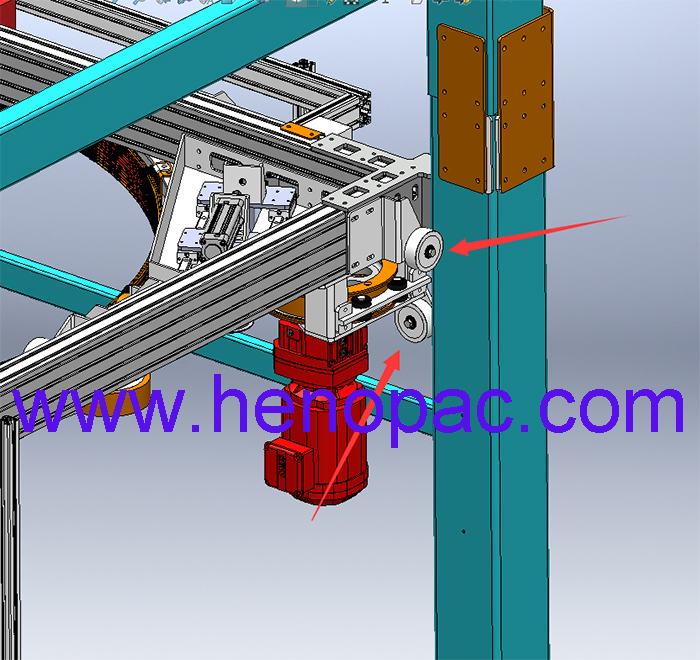

- fallproof device

- horizontal ring type driver

- arbitrary position can starting wrapping

- Product description: Rotary Ring type Automatic Pallet Wrapper Rotary Ring type stretch wrapper Ring Type High Speed Fully Automatic Pallet Wrapping Machine Automatic pallet wrapper with rotary ring

Rotary Ring type stretch wrapper

Ring Type High Speed Fully Automatic Pallet Wrapping Machine

Automatic pallet wrapper with rotary ring

Упаковщик поддонов с вращающимся кольцом

Loại vòng quay Pallet Wrapper

เครื่องพันพาเลทแบบวงแหวน

Envolvedora de paletas tipo anillo rotativo

Envolvedora de paletes tipo anel rotativo

Automatic high-speed ring type pallet wrapping machine suit for the packaging of goods in container ,bulk orpallet, which widely used in food and beverage industrial, electronic appliances, hardware mechanical and papermaking, printing, metallurgy and building materials industries, especially adapted to thelogistics industry application of packing in stereoscopic warehouse.

ItemIntroduction

1、customer demands

1.1 packing cargo:

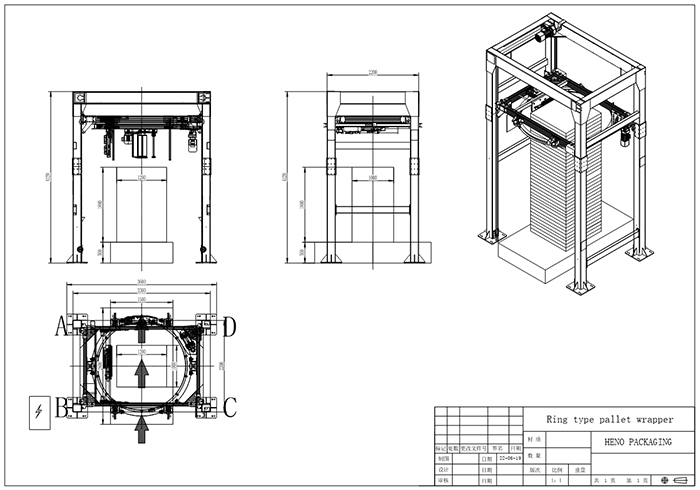

1.2 pallet cargo size:L1200*W1200*H1800 mm Max(can customized according to customer’scargo size

1.3 pallet cargo weight: 2000 kg

1.4 pallet size: L1200×W1200×H 135 mm

1.4conveyor line height:600mm(can customized according to customer’s height)

1.5 outside conveyor line width:1400mm

1.6packing speed: 60-70pallets/hour

1.7 land occupation:3400mm*2400mm

2、packing process

2.1、the pallet cargo automatic conveyor in place the packing position by the paleltconveyor line ,the ring type pallet wrapper get the start signal will pack the four side face of the pallet cargo . it will finished packing accordint to the pre-set paramter.automatic film clamp,cutting and welding ,then conveyor out.

3.packing materail

|

LLDPE stretch film |

widht:500mm |

|

thickness:17-35μm |

OD:260mm |

|

Paper ID:76mm |

Paper core lenght:500mm |

二、technical parameter

1 Main functions

PLCnprogrammablecontrol,top and bottom wrap circles and times can setting

1.2it can start pack at any position of the pallet

cargo,fit fordiversified

packing demands, Adapt to a wider range, flexible application, fast and efficient

1.3it can choose the fully automatic single layer packing model,bottom,middle,top and so on 30 kinds packing model according to packing demands ,saving the cost

1.4 Automatic detection the height by the photocell

1.5 it has the fault automatic diagnosis alarm, query processing and emergency stop function

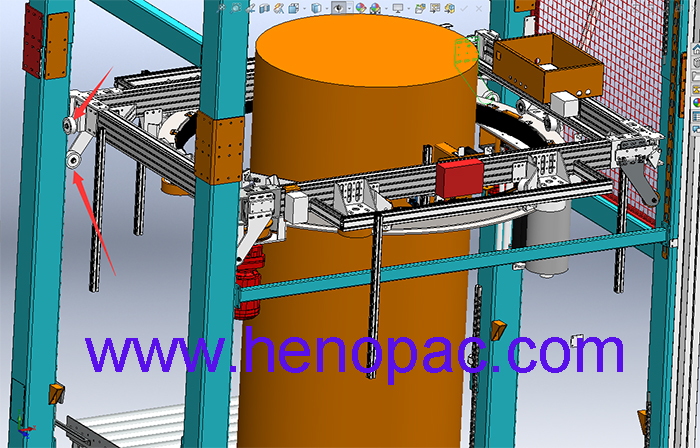

1.6 Adopt horizontal ring to driver,rotation is more stable and lower noise

1.7 it can three direction feeder packing cargo,Can realize multi-line parallel use

1.8 fall-proof: Anti drop system, adopt the spring cylinder and four sets two direction wheels device

2、mainly parameter

2.1、packing size:L1200*W1200*H1800 mm

2.2、packing speed:60-70 pallets/hour

2.3、conveyor line height:600mm(it can do according customer’s demands)

2.4、Power:6.0 KW

2.5、mahcine weight:2000Kg

2.6、rotary speed:45rpm/min(max)

2.7、voltage:380VAC 3phase 5lines 50Hz

2.8、Air consumption:1000ml/min

2.9、Air Pressure:0.5~0.7MPa

2.10、Equipment use occasion: room normal temperature

3、the ring

driver 1 set

3.1、Motor with inverter adjustable speed and with brake

3.2、motor and gear:SEW/Germany

3.3、power:P=1.5KW

3.4、driver change frequency adjsutable speed and with brake

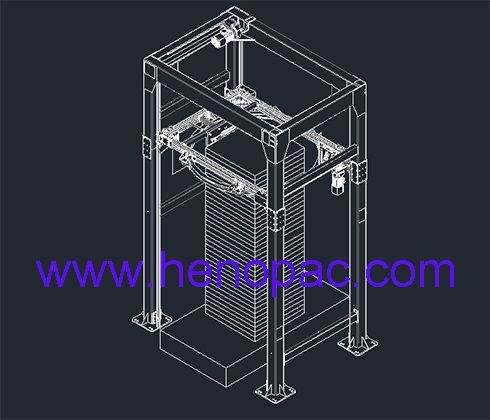

4、lifting mechanism

4.1、lifting adopt the chain to drive ,stable and highly reliable

4.2、lifting drive gear box:gearreducer

4.3、power:3.0KW

4.4、motor:SEW

4.5、driver change frequency adjsutable speed and with brake

5、frame parts

5.1 machine frame adopt the gantry ,material is Q235 steel

5.2 the frame install the drive support

6、film carriage parts

6.1、the film carriage install the photocell,Automatic detection the height of the cargo

6.2、film carriage AC motor power:1.1kw

6.3 film carriage feeder film motor:SEW

6.4、Powered pre-stretch film carriage, ratio is 250%

6.5、feeder film speed can adjustable by change the frequency

6.6、film carriage following mechanism

6.7、film carriage feed film swing Gyration,feeder film following is by proximity switch control the feeder film motor start and stop,

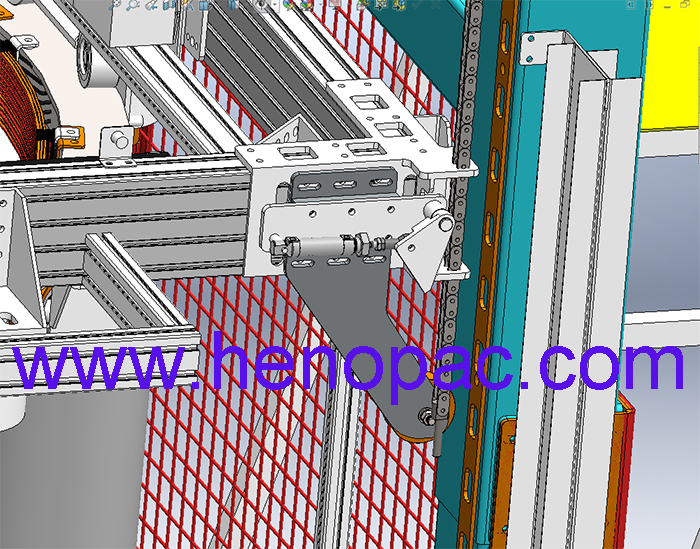

7、Automatic film clamp and cutting mechanism

7.1、it automatic cutting the film ,clamp film tail and weliding it when finished packing;

7.2、specially-made film clamp device and clmp andcutting program control ,it make sure it not has film tail;

7.3、fusing film adopt the heating welding

7.4、Pneumatic parts:SMC

8、saefty interlock mechanism

8.1、rotation,linfting and conveyor line interlock

9、The core component:

|

NO. |

Item |

From |

brand |

|

1 |

PLC |

Germany |

Siemenes/ S7-1200 |

|

2 |

HMI |

Germany |

Siemenes/ KTP700 |

|

3 |

AC frequency inverter |

Germany |

Siemenes/ G120C |

|

4 |

Cylinder |

Japan |

SMC |

|

5 |

Electric valve |

Japan |

SMC |

|

6 |

Photoswitch |

Germany |

Sick |

|

7 |

Air switch |

Germany |

Siemenes |

|

8 |

Limit switch |

Germany |

Siemenes |

|

9 |

AC contactor |

Germany |

Siemenes |

|

10 |

Motors |

Germany |

Sew |

|

11 |

Gear boxes |

Germany |

Sew |

10. optional

top presser ,top sheet dispenser,cardboard applicator ,roping system,conveyor line

11. fall-proof: Anti drop system, adopt the spring cylinder and four sets two direction wheels device

12.detail picture introduce:

Categories

- semi-auto stretch wrapper

- fully auto stretch wrapper

- pallet strapping machine

- automatic edgeboard applicator

- High speed tray former

- case erector

- Bag-in-box maker & inserter

- case packer

- Bag sealing and fold machine

- case sealer

- pallet dispenser/pallet magazine

- palletizer robot system

- pallet handing solutions

- palletizer robot relate

- mask machine

- mask packing machine

Latest News

Contact Us

Contact: David lee

Phone: +86 18680322634

Tel: 86-755-21508489

Add: Junyi Industries area, Lixin South Road, Foyong,Bao an District, Shenzhen, China

henopac

henopac henopac

henopac