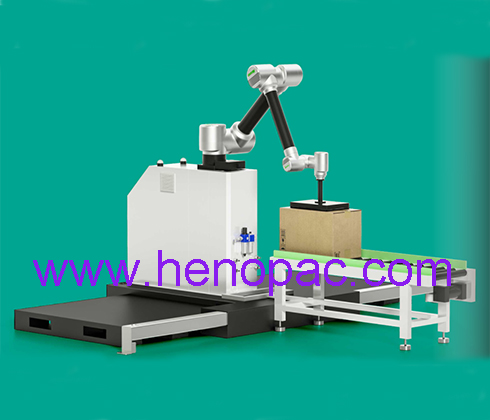

palletizer robot system

Collaborative Palletizing station

- vaccum gripper

- minimal footprint

- easy to operate

- very flexible

- Product description: Collaborative Palletizing System Collaborative Palletizing station collaborative robotic palletizer Palletizing Robot Solution Robotic Palletizing System coval modular vaccum gripper end-of-lin

Collaborative palletizing station

Collaborative palletizer robot

collaborative robot stacking carton box

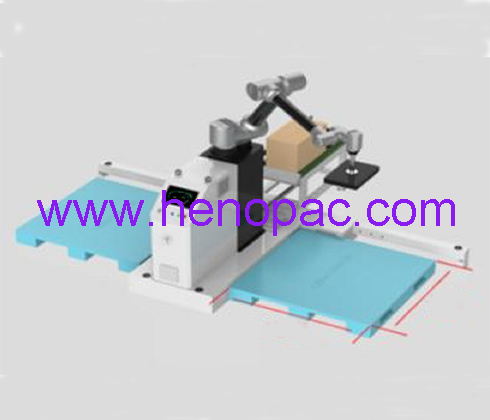

HENO packaging collaborative robot widely used in 3C , automobile, glass manufacturing, food processing, metal

processing, rubber and plastic industry ,covering fields of handling and palletizing, laser processing,loading and unloading, welding, cutting, grinding and polishing, gluing,assembly and labeling. this is the palletizing application.

Collaborative

palleitzer robot workstation

Technical details

Ø Payload: up to 20 kg

Ø Capacity: up to 8 CPM when load 20KG

Ø Item size:forming carton box (W×L×H) from 140×210×110 mm to 290×530×370 mm

Ø Pallet sizes: EUR, INDU, US, JPN and AUS < 1230*1230mm

Ø Pallet height, up to 2.1 m

Easy to control

The KEBA control system focuses on usability and intuitiveness. The operator is in full control of the palletizer – for straightforward, easy installation and configuration.

The drag and drop pallet manager also allows the operator to change and configure new pallet patterns in minutes.

Simply flexible

Thanks to a non-bolted installation, the robot palletizer meets the growing demand for flexibility in production. With its compact and modular design, a quick move can be made within a production facility for seasonal production changes or customized batches.

Ø NO SAFETY FENCES:Open, safe, guard-less layout without sacrificing speed

Ø CUSTOM EOAT:Compatible with Cases, Trays, Bags and more

Ø IMMEDIATE CONTACT STOP:Safely working side-by-side with humans

Ø DUAL PALLET & SLIP/TIER SHEET STATIONS

Ø Allow for uninterrupted operation

Ø minimal footprint

Ø Touchscreen HMI with easy to use interface and E-stop button

|

Collaborative palletizing robot station technical parameter |

|||

|

Base style |

Fixed base |

Lifing base |

|

|

Max load |

20kgs |

||

|

Machine weight |

260kgs |

300kgs |

|

|

Pallet working radius |

1600mm |

||

|

Floor space |

L3950*1720mm |

||

|

Fit fot max pallet size |

L1250*W1250mm |

||

|

voltage |

Sinlge phase 200-240V 50/60Hz |

||

|

power |

2.5kw |

3.3kw |

|

|

Palletizing max height |

H1650mm (include pallet height) |

H2100mm (include pallet height) |

|

|

Range of Motion(ROM) |

J1 : ±360° |

J1 : ±360° |

|

|

J2 : ±125° |

J2 : ±125° |

||

|

J3 : ±160° |

J3 : ±160° |

||

|

J4 : ±180° |

J4 : ±180° |

||

|

J5 : ±360° |

J5 : ±360° |

||

|

J6 : ±360° |

J6 : ±360° |

||

|

Motion max speed |

J1/J2/J3: 148°/s |

||

|

J4/J5/J6: 186°/s |

|||

|

Positioning accuracy |

±0.04mm |

||

|

Communication Type |

Modbus-TCP,EtherCAT,CAN,RS232/485 |

||

|

IP Class |

IP54 |

||

|

Temperature Range |

0-55º |

||

|

Main material |

Aluminum alloy, Carbon fiber |

||

Categories

- semi-auto stretch wrapper

- fully auto stretch wrapper

- pallet strapping machine

- automatic edgeboard applicator

- High speed tray former

- case erector

- Bag-in-box maker & inserter

- case packer

- Bag sealing and fold machine

- case sealer

- pallet dispenser/pallet magazine

- palletizer robot system

- pallet handing solutions

- palletizer robot relate

- mask machine

- mask packing machine

Latest News

Contact Us

Contact: David lee

Phone: +86 18680322634

Tel: 86-755-21508489

Add: Junyi Industries area, Lixin South Road, Foyong,Bao an District, Shenzhen, China

henopac

henopac henopac

henopac