case erector

plastic bag inserter machine Polybag in Box Bag Maker and Inserters

- Product description: plastic bag inserter machine Polybag in Box Bag Maker and Inserters

Full Automatic Plastic bag inserter machine

Applications:

For packaging various products such as food, electronic products, stationery, plastic products, hardware, screws, beverages and toys.

Applications:

The unit is suitable for various products such as frozen food, processed food products, agricultural products, electronic products, stationery, plastic products, hardware parts, toys, powders, and liquid foods

Features:

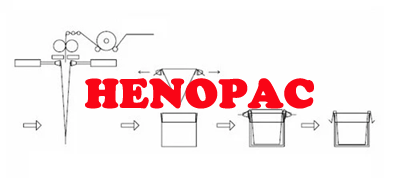

It can make bags with multiple lengths from a roll of flat or gushed film; places the bag into a carton and fold the top flaps of it over the edges

Different kinds of carton erectors can be linked

Adds a film-press device to make the observe bag which is especially suitable for food packaging

plastic bag insert machine, plastic bag inserter

seal carton bag,protecting cattering and dusting

Plastic bag insert machine are a great time and cost saving solution, that allows you to either fill directly into your box without other packaging, or to offer better protection for your precious product, by enveloping the product in a protect plastic bag layer.

Plastic bag insert machine suitable for different sectors, such as: food, electronic products, stationery, plastic products, beverages and so on.

From a tubular film roll, suction cups pick up the end of film and form the bag while the welding bar seals and cuts the bag.

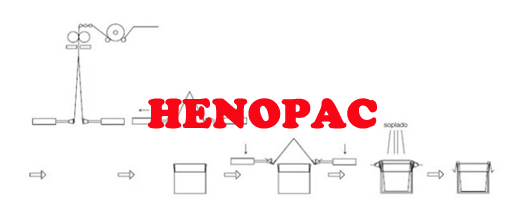

This machine has an inverted insertion. The bag is inserted into the outside part of the box top flaps and by a blowing system the bag is pressed against the interior walls and bottom of the box. The box is ready to be filled.

Outside insert way:

Technical features:

Production (according format) - up to 10 boxes/min.

Electric power - 110V/220V/380V/400V, 50HZ/60HZ

Installed power - 2 Kw

Pneumatic installation - 6 bar

Carton box size:L250-450*W220-400*H250 Film width - 400-600 mm (M folded barrel film)

Film thickness:30-100 microns (M folded barrel film)

Film length equation Box: L+W+150mm = required film length

PLC: Mitsubishi/Japan

HMI:Weinview/Taiwan

Servo motor: Mitsubishi/Japan

Servo driver: Mitsubishi/Japan

Cylinder: SMC/Japan

Valve: SMC/Japan

Photocell: Omron/Japan

Proximity switch: Omron/Japan

Inverter: Dongyuan/Taiwan

Relay: Omron/Japan

Motor:Liming/Taiwan

Gear box: Liming/Taiwan

bag inserting machine, bag inserter

Polybag in Box Bag Maker and Inserters

Applications:

For packaging various products such as food, electronic products, stationery, plastic products, hardware, screws, beverages and toys.

Applications:

The unit is suitable for various products such as frozen food, processed food products, agricultural products, electronic products, stationery, plastic products, hardware parts, toys, powders, and liquid foods

Features:

It can make bags with multiple lengths from a roll of flat or gushed film; places the bag into a carton and fold the top flaps of it over the edges

Different kinds of carton erectors can be linked

Adds a film-press device to make the observe bag which is especially suitable for food packaging

plastic bag insert machine, plastic bag inserter

seal carton bag,protecting cattering and dusting

Plastic bag insert machine are a great time and cost saving solution, that allows you to either fill directly into your box without other packaging, or to offer better protection for your precious product, by enveloping the product in a protect plastic bag layer.

Plastic bag insert machine suitable for different sectors, such as: food, electronic products, stationery, plastic products, beverages and so on.

From a tubular film roll, suction cups pick up the end of film and form the bag while the welding bar seals and cuts the bag.

This machine has an inverted insertion. The bag is inserted into the outside part of the box top flaps and by a blowing system the bag is pressed against the interior walls and bottom of the box. The box is ready to be filled.

Inserting Process:

Inside insert way:

Outside insert way:

Technical features:

Production (according format) - up to 10 boxes/min.

Electric power - 110V/220V/380V/400V, 50HZ/60HZ

Installed power - 2 Kw

Pneumatic installation - 6 bar

Carton box size:L250-450*W220-400*H250

Film thickness:30-100 microns (M folded barrel film)

Film length equation Box: L+W+150mm = required film length

PLC: Mitsubishi/Japan

HMI:Weinview/Taiwan

Servo motor: Mitsubishi/Japan

Servo driver: Mitsubishi/Japan

Cylinder: SMC/Japan

Valve: SMC/Japan

Photocell: Omron/Japan

Proximity switch: Omron/Japan

Inverter: Dongyuan/Taiwan

Relay: Omron/Japan

Motor:Liming/Taiwan

Gear box: Liming/Taiwan

Categories

- semi-auto stretch wrapper

- fully auto stretch wrapper

- pallet strapping machine

- automatic edgeboard applicator

- High speed tray former

- case erector

- Bag-in-box maker & inserter

- case packer

- Bag sealing and fold machine

- case sealer

- pallet dispenser/pallet magazine

- palletizer robot system

- pallet handing solutions

- palletizer robot relate

- mask machine

- mask packing machine

Latest News

Contact Us

Contact: David lee

Phone: +86 18680322634

Tel: 86-755-21508489

Add: Junyi Industries area, Lixin South Road, Foyong,Bao an District, Shenzhen, China

henopac

henopac henopac

henopac