case erector

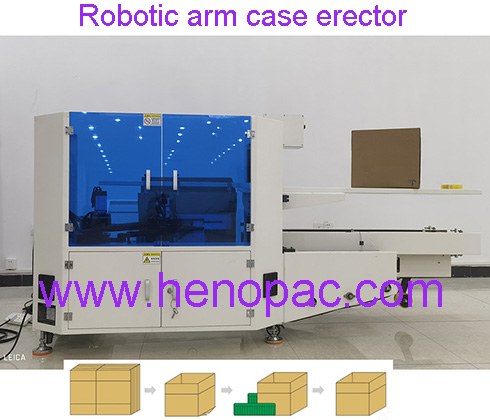

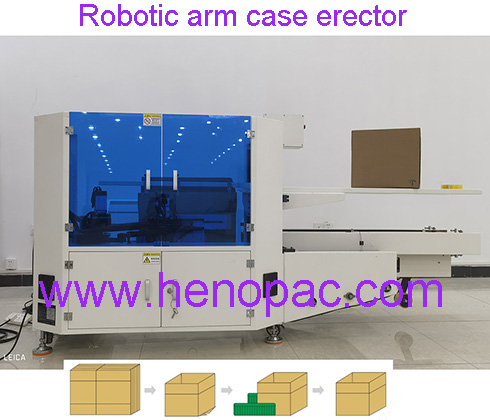

SK500 Robotic arm case erector

- adopt robotic arm

- total servo motor driver

- automatic adjustable accord to different case size

- high speed high cost effective

- Product description: Robotic arm case erector mechanical arm case erector servo case erector high speed case erector

SK500 Robotic arm case erector

mechanical arm case erector

servo motor driver case erector

high speed case erector

Robotic case erector is a machine designed to automate the process of forming and erecting cardboard boxes or cases. The efficiency and speed that robots bring to this process are critical for modern packaging operations.

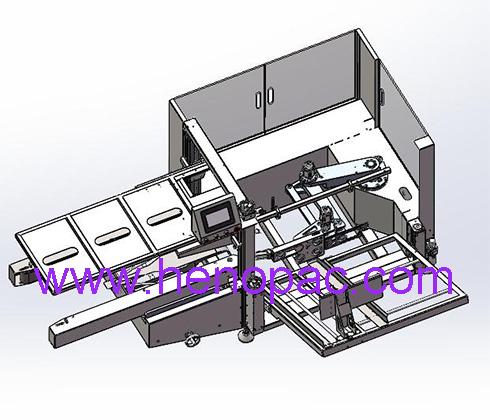

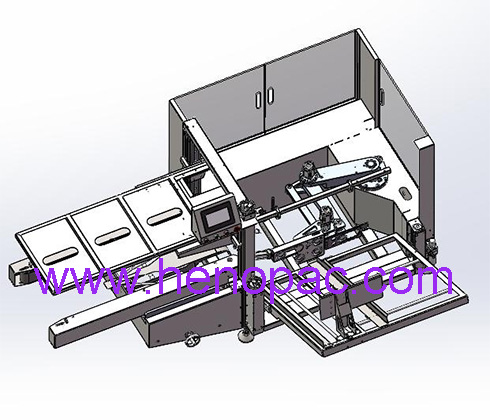

high speed robotic arm case erector is controlled by Leadshine controller and servos and operate from HIMI system. Machine can do 25 cartons forming and tapping in every min. very efficiency and convenient. Carton board can be loaded without stopping the machine. Reasonable design and fine processing of the whole machine. The whole machine is combined with in-feeder, tissue pile up device, and filling conveyor among which the pile up device is controlled by servos.

1. The machine can be equipped with side feeding unit and vertical feeding unit for different requirement.

2. The machine has precise case sending and will alarm if the cartons are missing.

3. When the machine stops, the machine will stop the conveyors for operator checking. The machine has overload alarm and can be reset by manually solve the overload problem and press the reset button to make the servo control system to back to the origin point(slowly back). n This machine has a simple structure, convenient operation, easy maintenance, and is widely used in various industries.

n The box adopts two servo motors to drive the belts on both sides, which can better ensure the synchronous operation of the belts on both sides and ensure that the cardboard box is square.

n The two sides of the box adopt an open structure, which provides better visibility and more convenient operation for the operator.

n The whole machine is highly automated when paired with a robotic arm,reducing manual labor.

n Low noise, smooth operation, and does not damage the cardboard box.

n The box storage adopts a tilted unpowered box storage design, which can replenish cardboard boxes at any time without stopping the machine.

n It can achieve seamless docking with front-end and back-end devices.

n The standard model is carbon steel spray painted (frosted silver), which can be customized according to customer needs.

Ø Technical parameter:

n Production speed 25 ctns/min max

n Carton size(mm) L240-500*W180-420*H150-500

n Power supply 220V、50/60HZ、 1∮

n Total power: 2.3KW

n Air comsumption 450kgf/ cm²

n Adhesive tape width 48/60/75MM (choose one)

n Machine dimension L2570xW2000xH1600mm

n Machine weight 450KG

n Servo Motor : Leadshine/China

n Servo driver: Leadshine/China

n planetary reducer: Laifual/China

n Relay:Omron/Japan

n Sensor: Sick/Germany

n Cylinder: AirTac/ Taiwan

n Magnetic Valve: AirTac/ Taiwan

n PLC :Leadshine/China (Exclusively for robots)

n Touch Panel:Kinco/china (Exclusively for robots)

n Vertical storage, cartons can be added at any time without stopping the machine;

n Suitable for forming and sealing cartons of the same size.

n Automatic adjust to change the carton sizes by touch screen;

Categories

- semi-auto stretch wrapper

- fully auto stretch wrapper

- pallet strapping machine

- automatic edgeboard applicator

- High speed tray former

- case erector

- Bag-in-box maker & inserter

- case packer

- Bag sealing and fold machine

- case sealer

- pallet dispenser/pallet magazine

- palletizer robot system

- pallet handing solutions

- palletizer robot relate

- mask machine

- mask packing machine

Latest News

Contact Us

Contact: David lee

Phone: +86 18680322634

Tel: 86-755-21508489

Add: Junyi Industries area, Lixin South Road, Foyong,Bao an District, Shenzhen, China

henopac

henopac henopac

henopac