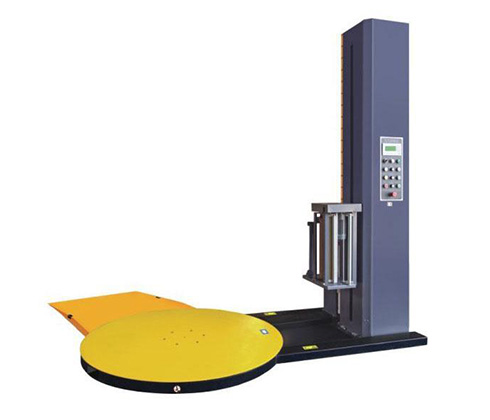

semi-auto pallet stretch wrapper

G5 Automatic Pallet Wrapper with Top Sheet Dispenser

- Product description: G5 Automatic Pallet Wrapper with Top Sheet Dispenser

G5 Automatic Pallet Wrapper with Top Sheet Dispenser

G5 Automatic is fitted with automatic film apply/cut unit, top sheet dispensing unit and remote control device. An operator is able to start and s

Product advantage

• Standalone wrapping & top cover machine

• Automatic film clamp, cut & seal

• Top cover to achieve rain-drop proof

Product resources

The main performance parameters

Features:

>> Two working mode choices: wrapping, or wrapping with top sheet dispensing.

>> PLC controlled, easy wrapping program setting.

>> Automatic stretch film clamp & cut, pneumatically driven.

>> Remote control device fitted. Machine start on control panel or remote controller.

>> Automatic film welding device for perfect film tail handling.

>> Film tension, turntable speed & carriage speed adjustable on panel.

>> Power stretch film carriage, ratio 250%, film savings.

>> Automatic wrapping according to pre-set parameters. Manual wrap mode as an option.

>> Auto height detection, machine home position, forklift sockets for easy moving.

>> Multiple safety protection measures for ensured operator safety.

Specifications:

Turntable diameter: 1800mm

Wrapping height: 2100mm

Loading weight: 2000kgs

Packing speed: 20-30 pallets/hour

Turntable speed: 3-15rpm, turntable soft start & soft stop

Turntable Height: 136mm

Air Pressure: 0.4-0.7Mpa

Top dispensing unit lifting speed: 5m/min

Top sheet pulling speed: 12m/min

Top sheet size: Width 1700mm,Length variable

Cut method: instant heater

Wrapping settings: wrapping cycles /top wraps /bottom wraps /overwrap

Carriage speed: 5m/min max

Power: 3PH 380VAC, 50/60Hz, 20A, 3kw

Machine Dimensions: 2960 x 2625 x 3100

Machine Weight: 1500kg

Film type: stretch film thickness 17-35microns, width 450-500mm, paper core 76mm, max weight 15kgs

Top Sheet type: PE film, thickness 50-75microns, width1600-1800mm, net weight 120kgs max

G5 Automatic is fitted with automatic film apply/cut unit, top sheet dispensing unit and remote control device. An operator is able to start and s

Product advantage

• Standalone wrapping & top cover machine

• Automatic film clamp, cut & seal

• Top cover to achieve rain-drop proof

Product resources

The main performance parameters

Features:

>> Two working mode choices: wrapping, or wrapping with top sheet dispensing.

>> PLC controlled, easy wrapping program setting.

>> Automatic stretch film clamp & cut, pneumatically driven.

>> Remote control device fitted. Machine start on control panel or remote controller.

>> Automatic film welding device for perfect film tail handling.

>> Film tension, turntable speed & carriage speed adjustable on panel.

>> Power stretch film carriage, ratio 250%, film savings.

>> Automatic wrapping according to pre-set parameters. Manual wrap mode as an option.

>> Auto height detection, machine home position, forklift sockets for easy moving.

>> Multiple safety protection measures for ensured operator safety.

Specifications:

Turntable diameter: 1800mm

Wrapping height: 2100mm

Loading weight: 2000kgs

Packing speed: 20-30 pallets/hour

Turntable speed: 3-15rpm, turntable soft start & soft stop

Turntable Height: 136mm

Air Pressure: 0.4-0.7Mpa

Top dispensing unit lifting speed: 5m/min

Top sheet pulling speed: 12m/min

Top sheet size: Width 1700mm,Length variable

Cut method: instant heater

Wrapping settings: wrapping cycles /top wraps /bottom wraps /overwrap

Carriage speed: 5m/min max

Power: 3PH 380VAC, 50/60Hz, 20A, 3kw

Machine Dimensions: 2960 x 2625 x 3100

Machine Weight: 1500kg

Film type: stretch film thickness 17-35microns, width 450-500mm, paper core 76mm, max weight 15kgs

Top Sheet type: PE film, thickness 50-75microns, width1600-1800mm, net weight 120kgs max

Categories

- semi-auto stretch wrapper

- fully auto stretch wrapper

- pallet strapping machine

- automatic edgeboard applicator

- High speed tray former

- case erector

- Bag-in-box maker & inserter

- case packer

- Bag sealing and fold machine

- case sealer

- pallet dispenser/pallet magazine

- palletizer robot system

- pallet handing solutions

- palletizer robot relate

- mask machine

- mask packing machine

Latest News

Contact Us

Contact: David lee

Phone: +86 18680322634

Tel: 86-755-21508489

Add: Junyi Industries area, Lixin South Road, Foyong,Bao an District, Shenzhen, China

henopac

henopac henopac

henopac